Setting up a versatile network infrastructure in your workplace demands intensive planning and execution. From the cable management to determining the placement of individual network components, it is a series of time-consuming tasks. At this point, the choice to turn an existing exhaustive task into an even more difficult job lies in your copper trunk cable preferences. Choosing to have pre-terminated copper trunk cable can help you cut down precious installation time by eliminating repetitive tasks such as field terminations or splicing during installation.

Why choose pre-terminated copper trunk cable?

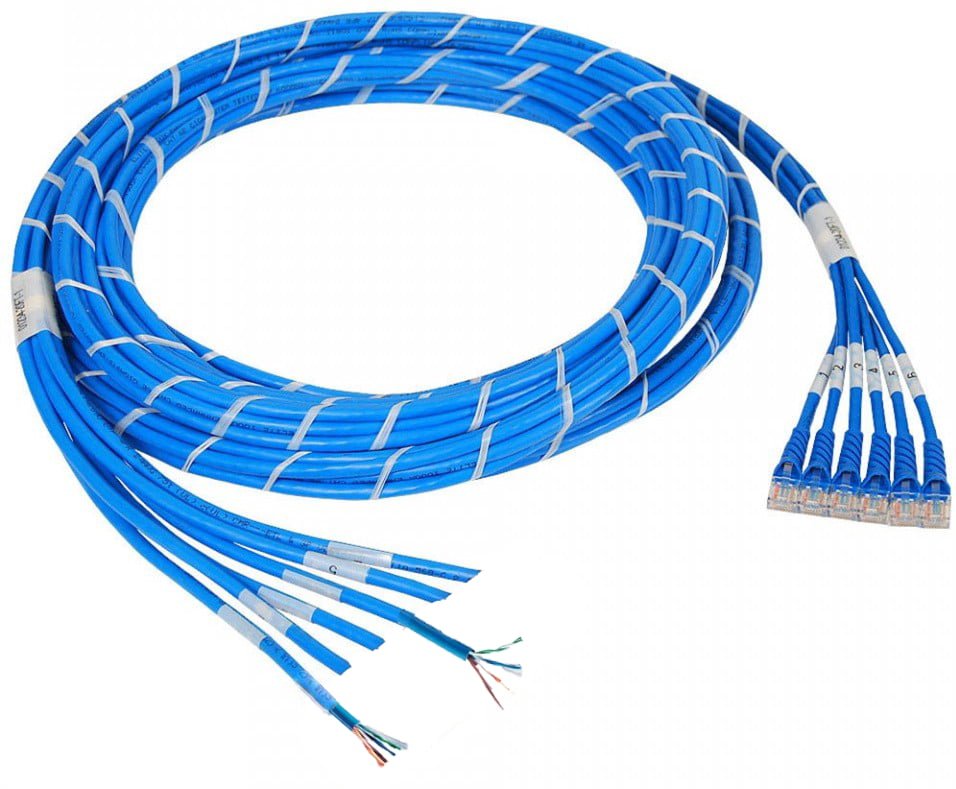

Copper cables are the backbone to your wired network and in order to connect two different network components in your infrastructure, you need to terminate the ends of copper cables with relevant connectors. Pre-terminated copper trunk cables are a bunch of copper wires that are terminated with appropriate terminals in the factory itself and tested for continuity.

Copper trunk cables are mostly available in 6, 8, or 12 bundles which eliminate the issues of cable management and make the data transmission between switches, servers, patch panels, and zone distribution areas in your data center easier. When laying out your network infrastructures with the pre-terminated copper trunk, you are ready to ‘plug-and-play’ as the cables are already pre-fitted with relevant connectors and so no need for on-site terminations. Moreover, pre-terminated fiber is ideally suited for when the cable distances are less than 100 meters and cable lengths are pre-determined.

Types of the pre-terminated trunk cable

The types of trunk cables are determined by three factors:

- Terminated connector type

- Fire rating of material used

- Average breakout length

Terminated connector type

- Jack to Jack: These types of trunk cables have a female-type connector (jack) on both ends of the cables. These act as a connection between patch panels on each end. These are laid for a permanent connection and the cables are run from within the walls for less wear and tear.

- Jack to Plug: These types of truck cable have a female-type connector (jack) on one end and a male-type connector (plug) on the other end. These can be used to extend the distance between two network components. These are more suitable for in-situ operations and remain open.

- Plug to Plug: Counterpart to the jack to jack trunk cables, the plug to plug trunk cable has a male-type connector on either end. These are used to make a continuation from the patch panels to the actual device.

- Jack or plug to open-end: These types of copper trunk cables will have a plug or jack on one end and the other end is open for termination on-site. These are the only trunk cables that need to be tested after installation.

- Jack or plug to cassette: This is mainly used for server end installations where one end has a cassette of plugs and the other end can be a plug, jack or even a cassette. This type of connection type eliminates the need for a connect point as the plug connects into the device.

%22%20transform%3D%22translate(1%201)%20scale(2.02344)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%2362b1ee%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-15.7%20293.6%20-345.5)%20scale(105.54106%2072.10563)%22%2F%3E%3Cellipse%20fill%3D%22%23fffff2%22%20cx%3D%22190%22%20cy%3D%22183%22%20rx%3D%2288%22%20ry%3D%2266%22%2F%3E%3Cellipse%20fill%3D%22%23ffffef%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(49.60518%2074.37983%20-32.23864%2021.5005%20243.2%2021.3)%22%2F%3E%3Cellipse%20fill%3D%22%23ffffec%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-45.6805%20-36.20592%2026.59387%20-33.55311%200%20167.8)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Jack Or Plug To Cassette %22%20transform%3D%22translate(2%202)%20scale(3.8789)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22166%22%20cy%3D%2293%22%20rx%3D%2256%22%20ry%3D%2256%22%2F%3E%3Cellipse%20fill%3D%22%2361625e%22%20cx%3D%22235%22%20cy%3D%22156%22%20rx%3D%22211%22%20ry%3D%2222%22%2F%3E%3Cellipse%20fill%3D%22%2376767a%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(10.8%20-35.6%201051.6)%20scale(102.9981%2027.79475)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-167.7%207.7%2024.2)%20scale(27.10934%20255)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Plug To Plug %22%20transform%3D%22translate(1.9%201.9)%20scale(3.73438)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%2349a3e5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(33.9%20-145%2090.3)%20scale(95.04028%2043.30956)%22%2F%3E%3Cellipse%20fill%3D%22%23fffffc%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-10%201238%20-436.6)%20scale(255%2060.52843)%22%2F%3E%3Cellipse%20fill%3D%22%235caaec%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(39.5%2053.6%20180.3)%20scale(111.64986%2032.86914)%22%2F%3E%3Cellipse%20fill%3D%22%23ffffeb%22%20cx%3D%22245%22%20cy%3D%2210%22%20rx%3D%2239%22%20ry%3D%2273%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Jack Or Plug To Open End %22%20transform%3D%22translate(1.2%201.2)%20scale(2.34375)%22%20fill-opacity%3D%22.5%22%3E%3Cpath%20fill%3D%22%237cada7%22%20d%3D%22M197.5%20118.5h-153v-65h153z%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-254.87417%208.00974%20-.82126%20-26.13306%20153%20162.8)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22155%22%20cy%3D%2213%22%20rx%3D%22255%22%20ry%3D%2221%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22243%22%20cy%3D%2294%22%20rx%3D%2226%22%20ry%3D%22255%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Jack To Plug

Jack To Jack

Fire rating of the material used

The cross-section of a copper trunk wire has an insulation layer wrapped over a dielectric material surrounding a copper wire core. Since most of the wires in network infrastructure are hidden behind walls or riser environment where there is enough airflow, you need to consider the possibility of fire. Special plenum-rated wires are needed in places where there is a chance of fire.

Average breakout length

As you may be aware, networking cables have a limitation on the length a signal can be transmitted without loss. The more length the cable can manage without repeating, the costlier it becomes. Moreover, you need to consider the average breakout length i.e. that length from the end of the braided sleeve to the connectors. This is an important factor when it comes to calculating the flexibility to route the cables as needed. Thicker cables will have lesser flexibility but higher data-carrying capacity.

Advantages of using pre-terminated copper trunk cables

In the modern workplace, time and efficiency are of the utmost importance when it comes to network management. Any downtime owing to troubleshooting and maintenance can cost a company dearly and this demands the need for quick cable installations providing reliable performance. So more and more companies are considering pre-terminated copper trunk cables. Here are some of the most common advantages of the pre-terminated copper trunk.

Improved deployment time

Unless you are using the pre-terminated copper trunk cables, most of your time would be invested in preparing the cable for termination and splicing the connectors. In fact, 75% of your installation time can be reduced by using pre-terminated over the on-site terminations.

No on-site testing needed

Except for the open-end terminated trunk cable, all the copper trunk cables are tested in the factory before being deployed. This pre-testing not only saves time but also the money invested.

Easy plug and play possibility

You have the choice of connectors that shall be pre-fitted and all you need to do is unbox the cables and plug into a relevant panel and you are ready. Additionally, with the cassette format, server-side installation becomes very quick.

Easy cable management

Since the cables are available in 6, 8, or 12 bundles, it is very easy to lay the cables as well as routing it as per your room dimensions. This also eliminates excess loops, reducing signal loss.

Wrapping Up

Nothing can replace pre-terminated copper trunk cables as the backbone of data centers and other networking infrastructure. With advantages such as plug and plug, near to zero testing times, lesser deployment times as well as flexible and reliable cable management, you can rest assured about your investment when it comes to pre-terminated copper cables.