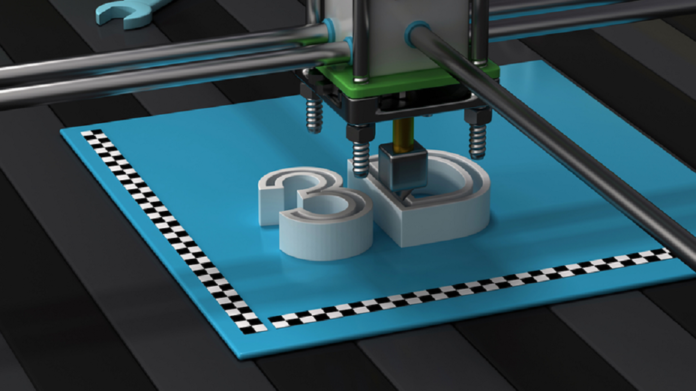

3D Printing, also famous as additive manufacturing, is the most affordable and agile choice for manufacturing little to medium-sized amounts of plastic and certain metal items—from modern parts and purchaser merchandise to useful models and aesthetic models.

Added manufacturing makes products layer by layer, in contrast to subtractive manufacturing (machining), which eliminates material from a solid block, or formative manufacturing (infusion forming or thermoforming), which shapes items utilizing molds. This makes 3D printing novel among manufacturing innovations in that it requires no tooling or other arrangement costs and can start producing immediately.

Accordingly, 3D Printing considers quickened product development cycles, and an unequaled economy for low-volume is fabricating. Due to the unique systems of additive manufacturing, 3D Printing can, without much of a stretch, accomplish designs that would be inconceivable with some other technology, opening the path for new item advancements to diminish part weight, dispose of gatherings and improve performance.

What is 3D Printing?

3D Printing builds parts and items layer by layer utilizing various techniques to fuse and solidify those layers. Before the 3D printing cycle can start, computerized 3D models must be separated into 2D cross-areas that the printer would then use to manufacture parts for each layer in turn. This is cultivated in G-code, the machine language of 3D printers. The technology for making these layers differs by the printer and incorporates melding liquefied fibers, sintering with lasers, or restoring with UV light or restricting operators. Some 3D printers consolidate multiple techniques.

These diverse 3D printing technologies offer a broad scope of materials that is continually developing. While plastics are the most widely recognized, new metal printing technologies like ExOne’s direct material printing have significantly expanded 3D printed metals’ affordability. 3D printed materials can be inflexible or rubbery and offer numerous synthetic, warm, and mechanical properties. It’s even conceivable to 3D print with sand to make sand shapes and centers.

In contrast to different technologies, the unpredictability of a design doesn’t affect a 3D printed part’s expense. 3D printed components can be utilized with their machine finish―which shifts in quality by the kind of machine―or can be done physically. The expense of 3D Printing is restricted to materials, print speed, part size, and any extra post-preparing.

Here, we answer every one of these questions and look at how 3D Printing analyzes to conventional manufacturing to assist you with understanding the present status of the technology.

When was 3D Printing Invented?

The idea of 3D Printing developed during the 1980s. In the mid-1980s, the innovation was alluded to as “Radio Prototyping.” At that point in 1984, Charles Hull applied for a patent for his design known as stereolithography.

The innovation considered the restoring of photosensitive sap layer by layer, making a part or object. He got the patent in 1986 and built up his organization 3D Systems. In 1987, the organization delivered its first item, the SLA-1. Frame dispatched 3D Printing into the technology business, and his organization is currently one of the most prominent 3D printing organizations.

How Does 3D Printing Work?

3D Printing all beginnings with making or downloading a computerized model. The model can be made utilizing a 3D scanner, demonstrating programming or application. When the model is finished, cutting programming is used to isolate the model into many flat layers. After this, you transfer the advanced STL or VRML record to the printer. The 3D printer deals with the rest by making the object. Contingent upon what is being made, the cycle can take hours to days.

The cycle consistently starts with a computerized 3D model – the diagram of the physical object. This model is cut by the printer’s product into thin, 2-dimensional layers and afterward transformed into many instructions in machine language (G-code) for the printer to execute.

From here, how a 3D printer works differ from the process. For instance, work area FDM printers liquefy plastic fibers and lay it down onto the print stage through a spout (like a high-exactness, PC controlled paste firearm). Large industrial SLS machines utilize a laser to dissolve (or sinter) dainty layers of metal or plastic powders. The accessible materials additionally shift by measure. Plastics are, by a long shot, the most well-known; however, metals can likewise be 3D printed. Again, the created parts can have a broad scope of explicit physical properties, extending from optically obvious to elastic-like objects.

3D Printing Benefits

- No costly tooling or other beginning up costs

- Fast turnaround―as small as one day with Multi Jet Fusion or ColorJet

- Easy configuration changes at no extra expense

- Complex calculations

- Combine multi-part congregations into a solitary piece

- Reduced stock and overhead through without a moment to spare manufacturing

- No waste of material

When to use 3D Printing

Although initially utilized for prototyping, new developments have made 3D Printing practical for little to medium production runs. So when does it bode well to use 3D Printing? Likewise, with most manufacturing questions, the appropriate response must be resolved dependent upon the situation. Notwithstanding, the prior in your item improvement measure you begin considering 3D Printing, the more it can profit your production.

The following are some characteristics that may demonstrate that a project is a decent contender for 3D Printing:

- Littler parts that would be hard to machine

- Creation of under 1000 units

- Advancing plans or tooling for product development

- Profoundly redid items like prosthetics or portable amplifiers where each unit is novel

- Complex calculations, settled centers, or single-piece leaves behind cylinders that would be difficult to machine or form

- Lightweight parts with solid grid insides

- Natural shapes

Choosing the Right 3D printer

- Prior we get into the various types of printers and materials accessible, there are a couple of crucial components to consider while figuring out which 3D printer is most appropriate to a task:

- The first and most significant is the reason for the project. Is this for The product, modern part, functional model, proof-of-concept, or aesthetic model? The response to this inquiry will, for the most part, lessen your choices to two or three printers.

- The following thought is whether there are particular material prerequisites for the project: heat resistance, chemical resistance, erosion obstruction, and biocompatibility.

- Ultimately, organizations should consider the number of units they need to request and how enormous each piece is. Printers scale contrastingly with part size and amount, so these contemplations will probably be the most significant monetary factor for any project.

If your 3D printer is having any issue and you are looking for its repair so, contact Advanced Electronic Services (AES). And, if you are looking for high-quality 3d printing powder, contact Stanford Advanced Materials (SAM).