Manufacturing PCBs is not always cheap. They are very important parts of technology so it is vital that you do not take any shortcuts when it comes to quality if you are trying to cut back on costs. Here are some top tips to help you achieve high-quality PCBs at a low-cost price.

Start with Good Software

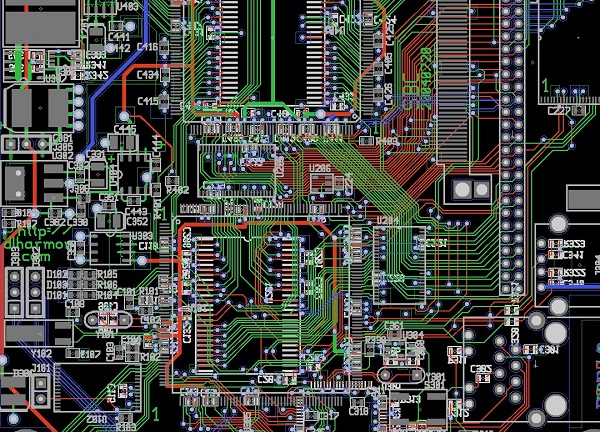

The best way to start saving money on your PCBs is all the way back in the design stage. By choosing a high-quality, multifunctional circuit designer software such as the highly recommended Altium, you will be able to use all the tools you need in one program. There is no need to invest in multiple programs if you can find one which does everything. Have a look around to see if you can find everything you need.

Find a Reliable but Low-Cost Manufacturer

The manufacturing process is one where you are likely to run up a lot of costs. By shopping around to find a better manufacturer, you might be able to find one who can make your circuit boards to the standard you expect for a much lower price.

There are, of course, some things you need to guarantee. You should make sure they have all the necessary certificates and licences they need to make your PCBs. They should also have the necessary equipment and technical knowledge so you know for definite that they will be able to fulfil your order.

Learn How to Optimise Your PCBs

Unsurprisingly, the cost of a PCB increases with the more components and layers to add. If you can learn how to strip back your designs and simplify them, you may be able to save some costs on manufacture. Lowering your layer count and optimising the size and shape of your PCBs may be a great way to ensure that your costs are down without sacrificing any of your product quality.

Choose the Right Finish

Did you know that the surface finish of your

Don’t Neglect Inspections and Tests

In the search for cost-effective PCBs, you may be tempted to shirk a round of testing or inspections if it means it cuts cost. However, if you are committed to producing high-quality PCBs, you simply cannot skip the tests. They are vital for confirming your product’s performance and potentially unmasking a fault that had otherwise gone undetected.

These are just some of the things you can do to help cut costs in your PCB manufacture. You should always aim for a high-quality product but that doesn’t mean it has to be high in cost. Balancing the two will be a great skill which will help you to be a much better designer overall.